The MP ultra-precision surface-mount resistor series from Alpha Electronics offers a wide resistance range from 30Ω up to 30kΩ with tight tolerances down to +0.05% (100Ω to 30kΩ), all in a small surface-mount package. By utilising Alpha’s Bulk Metal® foil resistor technology, they are able to produce resistors with low-temperature coefficients and excellent long-term stability. The Alpha MP series J-lead terminals provide flexibility compared to standard fixed surface-mount resistors as the resistive element internally is mechanically isolated from the leads via gold wire-bonding. The series exhibits excellent high-frequency characteristics thanks to their Bulk Metal® foil resistor technology, making them suitable for the most demanding precision applications.

- Surface-mount ultra-precision resistor

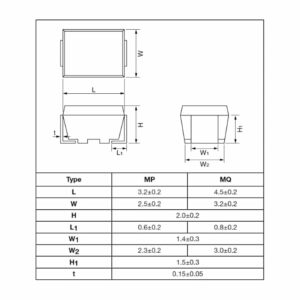

- Moulded package with J-lead terminations

- Resistance values from 30Ω to 30kΩ

- Tolerance of ±0.05% or ±0.1% (dependant on resistance values)

- TCR of ±5 ppm/°C or ±10 ppm/°C (dependant on resistance values)

- Temperature range from -65°C up to +175°C

- Maximum working voltage of 50V

- Maximum working current of 0.35A

- Power rating of 0.1W (at +125°C)

Typical applications for the MP ultra-precision surface-mount resistor series include:

- Sceintific instrumentation

- Test & Measurement equipment

Alpha Electronics MP Series Specification Table

| Attributes | Value |

|---|---|

| Resistance value | 30Ω to 30kΩ |

| Tolerance | ±0.05% / ±0.1% |

| TCR | ±5ppm/°C or ±10ppm/°C (-55 to +125°C) |

| Temperature range | -65°C to +175°C |

| Power rating (at +70°C) | 0.1W |

| Maximum voltage | 50V |

Alpha Electronics are manufacturers of some of the most stable and precise resistors on the market. As part of the VPG Foil Resistors product group, the Alpha Electronics brand is globally rewarded for the accuracy and reliability of its Bulk Metal® Foil technology resistors. Alpha Electronics has been living the conviction globally known to engineers for consistently delivering the highly desirable characteristics of “Stability, Accuracy and Reliability”. Please visit https://www.alpha-elec.co.jp for more information.