The FNP high power precision shunt resistor series from Alpha Electronics offers a range of very high precision current sensing shunts with a maximum power rating of 500W on a suitable heat sink at +25°C. By utilising a Ni-Cr Bulk Metal® foil resistor technology, they are able to produce resistors with low temperature coefficients. The FNP shunt resistor series has a built in Pt100 sensor for monitoring the temperature of the resistive element.

- High power precision shunt resistor

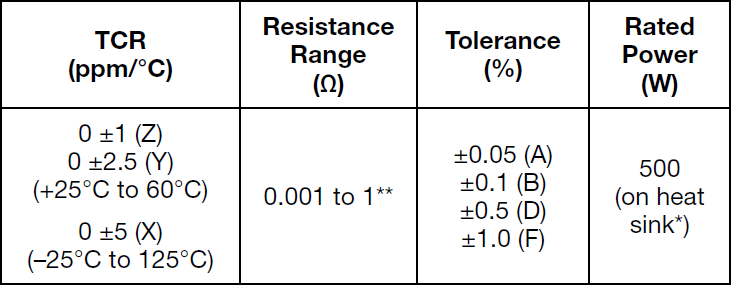

- Available in any resistance between 0.001Ω and 1Ω (higher values may be available upon request)

- Tight tolerance options as low as ±0.05% available

- Tight TCR options available of ±1 ppm/°C and ±2.5 ppm/°C (+25°C to +60°C) or ±5 ppm/°C (-25°C to +125°C)

- Maximum rated power of 500W

- Maximum working current of 320A

- Maximum rated operating temperature +75°C (resistance values greater than 0.01Ω, +25°C for resistances of 0.01Ω or below)

- Temperature range from -55°C up to +125°C

- Single pulse power load of 50J (<10ms)

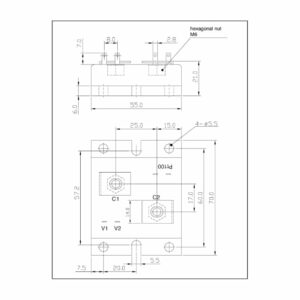

The Alpha Electronics FNP precision shunt resistor series are constructed out of the following materials:

- Base plate – Nickel-plated Copper

- Current terminals – Nickel-plated Copper (T = 1.0mm)

- Voltage and Pt terminals – Nickel-plated Copper (T = 0.5mm)

- Package – PPS injection-moulded case

Alpha’s Ni-Cr Bulk Metal® foil resistor technology means these high power precision shunt resistors resistors are ideal in applications like:

- Output reference of precision power supply

- Reference of charge-discharge test for high capacity batteries

The below table gives a summary of the specifications and options available for the Alpha FNP series:

* Keep temperature of the resistive element surface less than +125°C

** Please contact us for higher resistance values