By David Beatson, Joint Managing Director, Rhopoint Components

Specialised pressure sensors play a silent but vital role in artificial lift operations across oil and gas fields, especially where direct measurement under harsh conditions can make or break production success. The journey to reliable sensor technology for these demanding environments is an exercise in engineering discipline and rigorous application analysis – a story illustrated by the experience of one customer whose needs led to substantial evolution in sensor design and deployment.

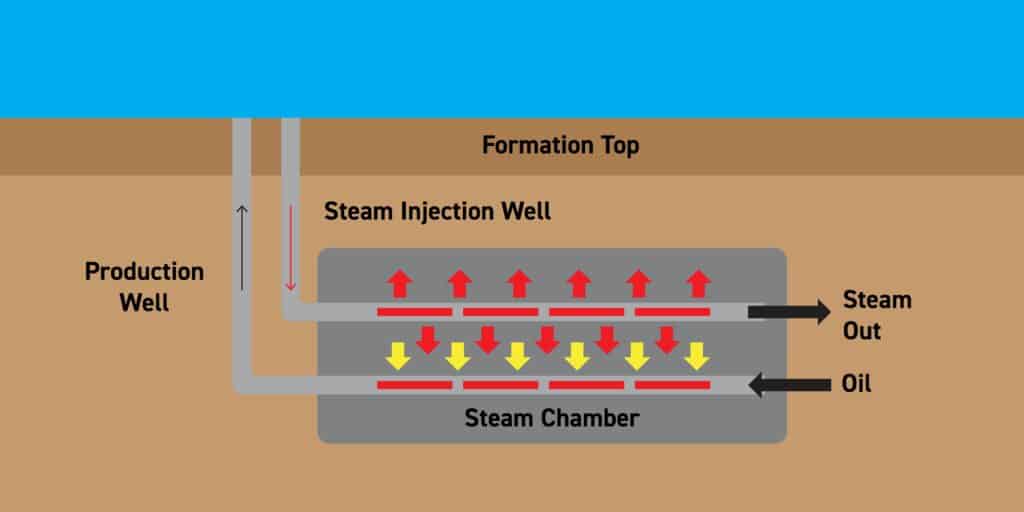

Artificial lift is a critical step in oil recovery, coming into play when natural reservoir pressure dwindles and gravity alone no longer drives hydrocarbons to the surface. High-temperature methods such as steam-assisted gravity drainage, chemical injection and submersible pumps allow fields to remain productive far beyond their primary lifespan. Yet these techniques introduce some of the harshest operational environments in the sector. Measurement reliability, especially of pressure in low-pressure, high-temperature (LPHT) systems becomes both technically complex and operationally crucial. For this reason, a customer approached Rhopoint Components to tackle a set of challenges that highlight the importance of getting every detail right when specifying sensors for artificial lift.

What makes these applications especially difficult for engineers is not simply the headline numbers for pressure or temperature. Post-primary recovery oil wells endure constant change, shifting from mild to extreme thermal loads as super-heated steam is injected at 250°C to loosen tarry oil and enable extraction. The fluid mix in the well can contain oil, gas, water and plenty of abrasive contaminants like sand. Each one of these is a test for sealing integrity and material choices. Meanwhile, vibration and shock levels escalate, particularly where surface diagnostics or progressive cavity pump monitoring are added. For measurement systems, risks mount quickly: seals may degrade, electrical drift can render readings meaningless and sensor internals may simply fail under stress. Inaccurate readings can severely jeopardise pump performance.

For an engineering design, specifying a pressure sensor for LPHT operation means thinking well beyond any generic datasheet. It starts with a precise definition of the operating environment: working pressure range (perhaps 0–10,000 PSI), proof pressure (roughly 1.5 times working, where sensor lifespan might erode), and burst pressure (2 times working, failure inevitable). Any spike from hydraulic fluid or instrument malfunction can push sensors past safe limits. This is not just theory, as our customer discovered. Their original installation met specification on paper, yet once surface monitoring for PCPs was introduced, shock and vibration quickly rose far beyond initial expectations. Catastrophic failure was a real risk until the analysis showed the internals could be reinforced, giving the sensors the ability to survive mechanical stress.

Material selection is key in this engineering process. The question “what is the media being measured?” is the starting point. For many downhole pressure sensors, exposure is limited to only wetted areas, allowing more cost-efficient configurations. But when external body exposures to pressure or corrosive fluid are unavoidable, choices like Inconel 718 or 725 become necessary for their unmatched corrosion resistance. The design must take into account not just immediate compatibility but also the long-term stability of sealing, diaphragm and electronics – all engineered to withstand repeated cycles of temperature and pressure extremes.

Signal quality and output architecture are equally crucial yet sometimes overlooked. Conventional high-temperature sensors may operate at 2.6 millivolts per volt output, which is workable but produces a weak signal vulnerable to electrical noise, especially over long cables in sprawling production sites. The customer’s solution was a sensor design delivering up to 10 millivolts per volt, raising the signal above the background interference and ensuring real readings when operators needed them most. Equally, standard-sized pressure ports proved inadequate at low working pressures typical of artificial lift, only stabilizing readings beyond 3000 PSI. By enlarging the port, the sensor could provide reliable outputs in ranges as low as 1000 PSI, fitting the application’s true requirements.

With over fifteen years of continuous service, the bespoke LPHT sensor has demonstrated the payoff of tailored engineering. Any operational failures traced back not to design flaws, but to incorrect handling by operators which is a clear testimony to how robust the device had become once matched perfectly to its environment. The downstream benefits have been clear: downtime dropped, control over artificial lift cycles improved and maintenance interventions became more predictable and less urgent. These are not sales claims but lessons from the evolving needs and responses of engineers in the field.

What emerged from this and similar projects is a set of engineering lessons stretching well beyond the oil patch. Aerospace and geothermal energy sites, as well as chemical processing facilities, confront strikingly similar tests. High temperatures, vibration, chemical attack, and drifting calibration are universal enemies. The advice is consistent: define not just the average operating conditions but all extremes that may be encountered. Reinforce sensor internals for ruggedness, match materials precisely to the exposure – whether local or across the whole sensor and prioritise strong, reliable electrical outputs for usable data regardless of cable run length. Calibration data provided in digital form, accessible via serial numbers online, now streamlines integration with monitoring networks and makes it easier to maintain traceable performance records.

Engineers tasked with sensor selection for artificial lift or any other extreme application should resist the temptation to retrofit general-purpose devices for specialised environments. The experience of the customer in this case, working alongside technical experts at Rhopoint Components highlights the success of environment-driven design. The future of measurement technology in extreme sectors is moving toward miniaturisation, digital calibration and networked data. But first and most importantly it is necessary to get the operating environment analysis right.

Designing for extremes environments is a speciality of Rhopoint Components. Performance and reliability depend on recognising every risk and engineering for every stress, from thermal loads to signal integrity. In this way, sensors become true enablers of safe, effective, and long-term production, even when the environment is actively working against them.