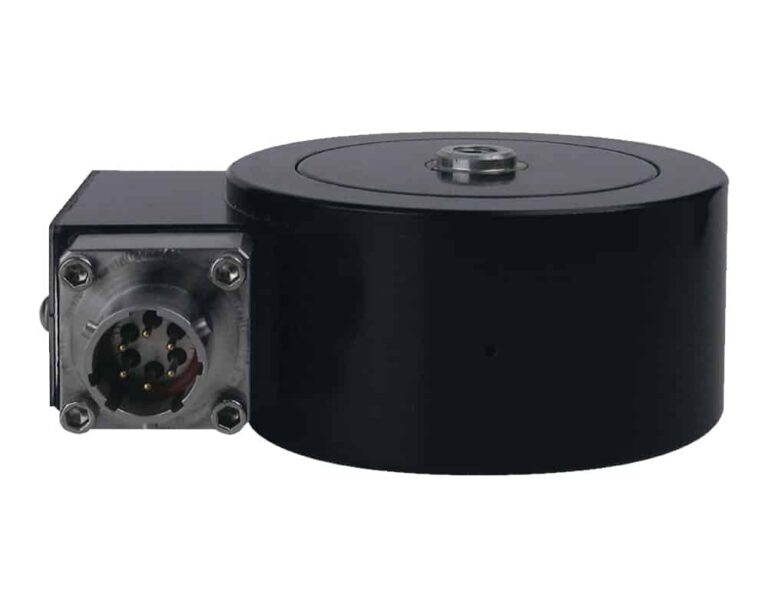

Stellar Technology is a sensor company specialising in the design, manufacture, and service of pressure transducers, pressure transmitters, load cells, force sensors, torque transducers, and temperature transducers.

From sensor engineering, electronics development and component machining to final assembly and testing, our engineers use the latest tools for design, analysis and documentation. Our machining capabilities include 5 axis milling and 8 axis turning.

Our electronics development capabilities include circuit design and analysis, PCB development and layout, and firmware/software development. In manufacturing, we are certified to the highest level of space grade soldering, qualified in TIG and laser welding, certified in configuration control practices, cleanliness practices, and traceability control.

For their official website, please visit www.stellartech.com