Rhopoint Components Ltd is a distinguished partner of industry-leading pressure sensor manufacturers, including Core Sensors, Merit Sensors, and Emerson Paine. This collaboration has established Rhopoint as a prime source for an extensive selection of pressure sensors tailored to meet the requirements of diverse applications across various sectors. The industries served include aerospace, automotive, downhole operations, medical, storage and transport, subsea environments, and other applications in harsh environments. This wide-ranging applicability underscores Rhopoint’s commitment to delivering solutions that cater to the specific needs of each sector, ensuring optimal performance and reliability.

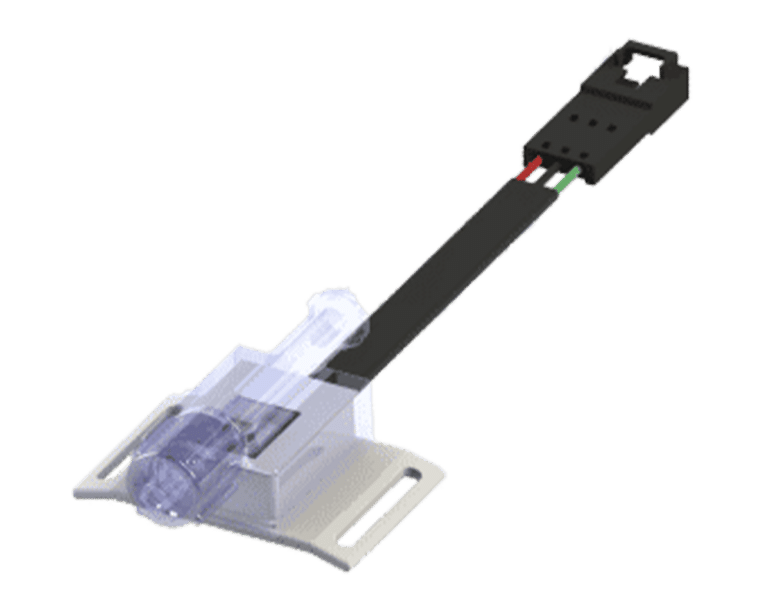

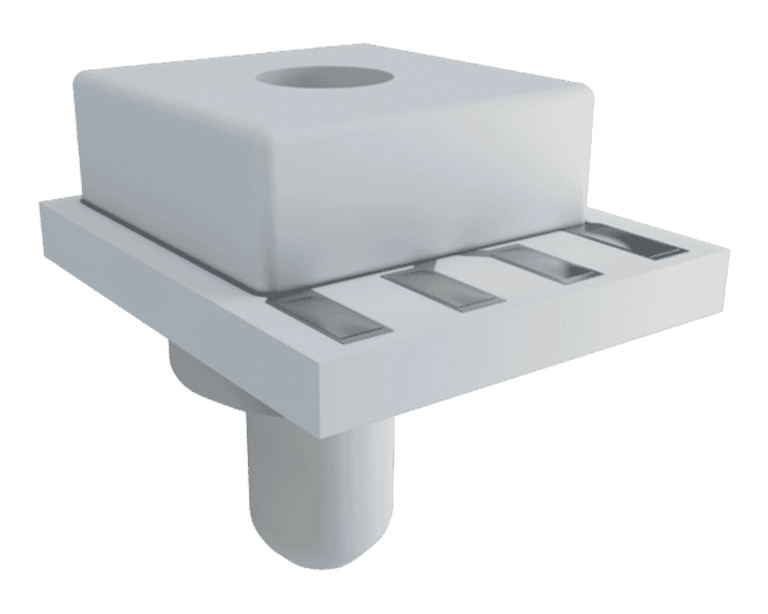

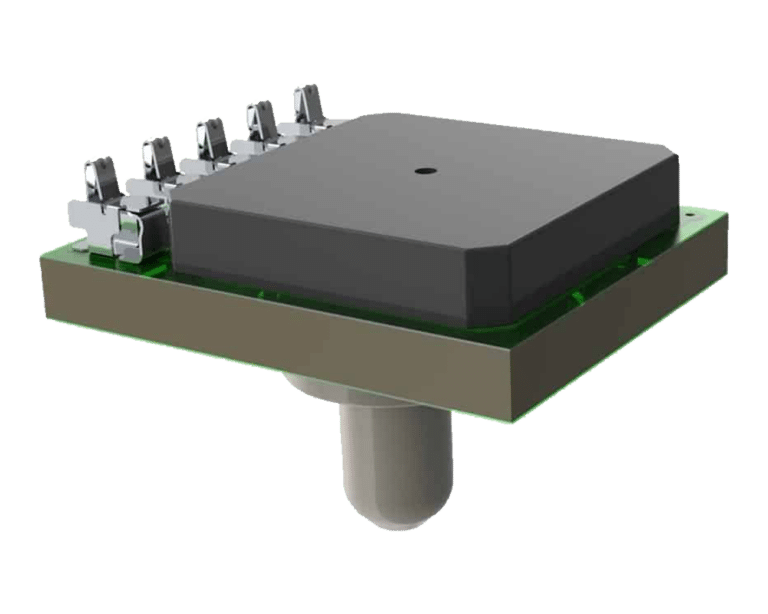

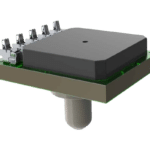

To address the unique demands of these varied applications, Rhopoint offers products with specific certifications and features. For example, select sensors are ATEX Certified, making them suitable for explosive atmospheres, while others are available in surface mount form, particularly for medical device integrations. This versatility is further enhanced by offering sensors designed for specific environmental conditions and applications, including differential, digital output, high temperature, industrial, level transmitters, space-approved, and submersible sensors. Each category is curated to provide precise, reliable measurements under the conditions for which they are intended.

Understanding the critical nature of selecting the right pressure sensor for your application, Rhopoint’s technical sales team is available to provide expert advice and support. Whether your project requires detailed technical guidance or you are seeking to understand the best product fit for your application, our team is equipped to assist you.

Need more information? Speak to our technical sales team who can discuss your project or product and provide technical advice. Speak to us now!