For over 25 years we have been supplying customers with accurate and reliable piezoresistive MEMS pressure sensors.

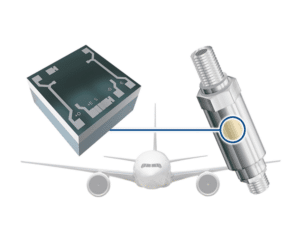

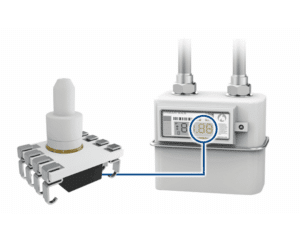

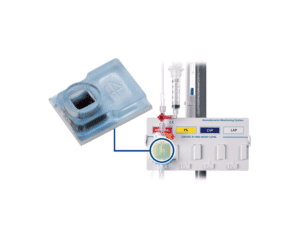

Merit Sensor Systems, Inc. partners with Rhopoint and it’s customers to design, fabricate, assemble and package reliable, cost-effective piezoresistive pressure sensor solutions for automotive, medical, industrial, aviation, defense and consumer applications.

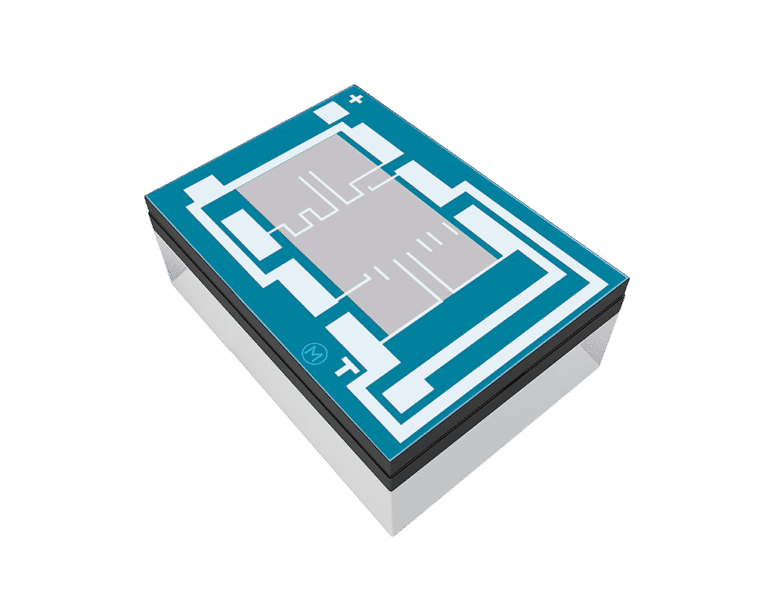

We design and manufacture piezoresistive pressure sensors (a type of MEMS) that measure pressure from 0 to 15,000 psi in sensing environments from -40 to 150 °C. Our sensors are available in absolute, gauge, vacuum, and differential configurations.

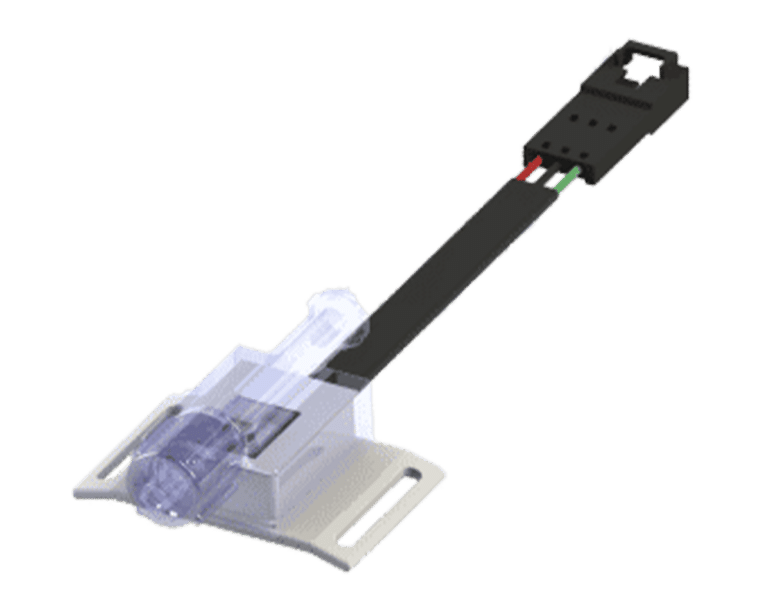

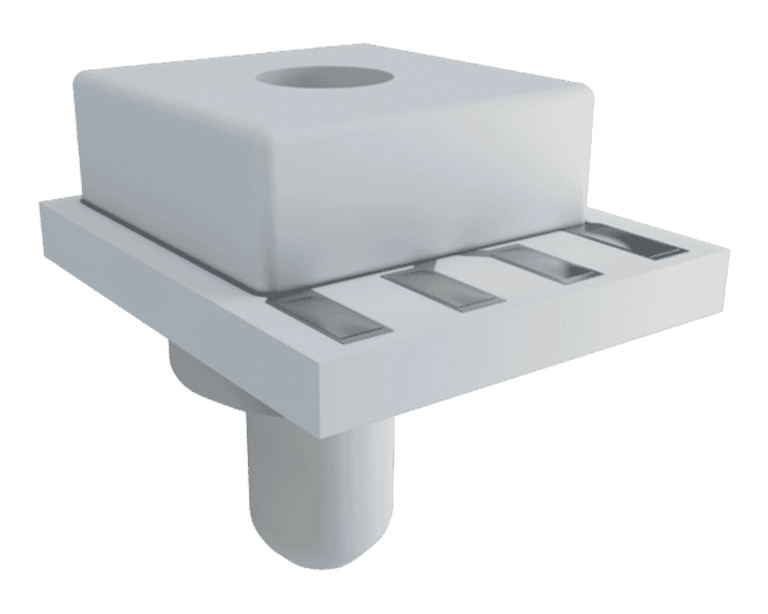

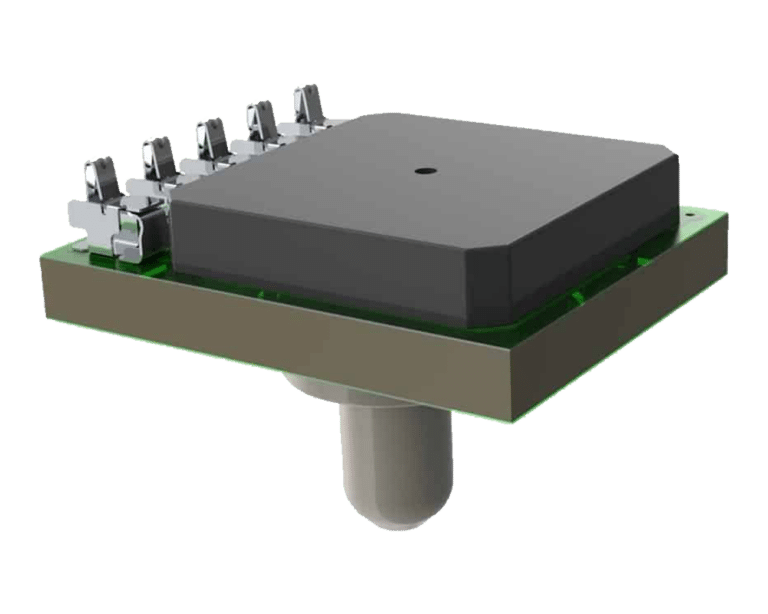

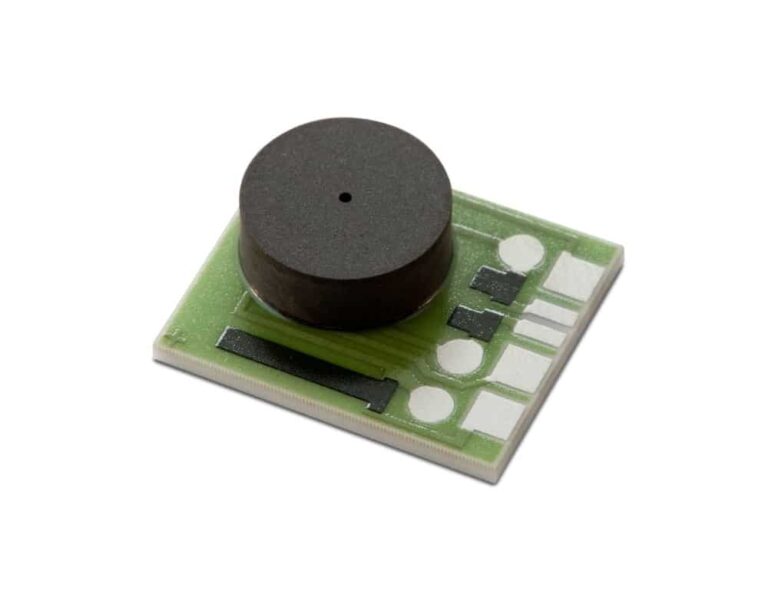

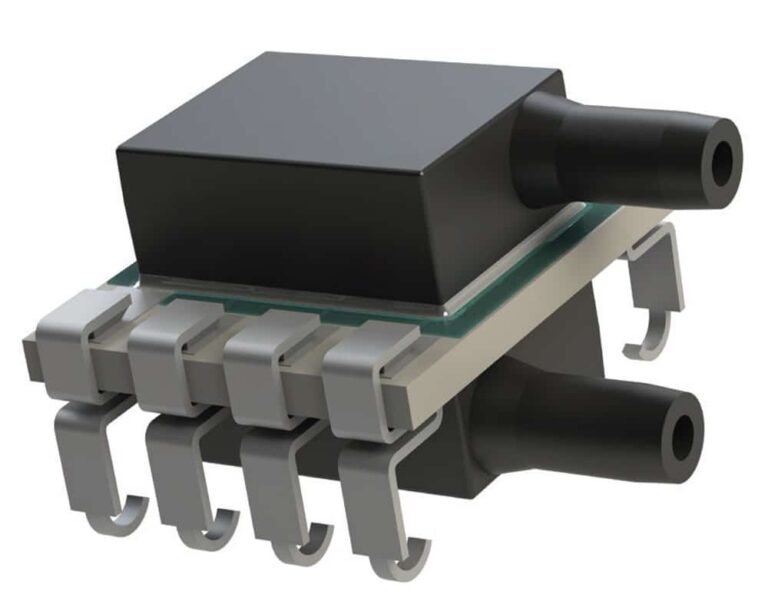

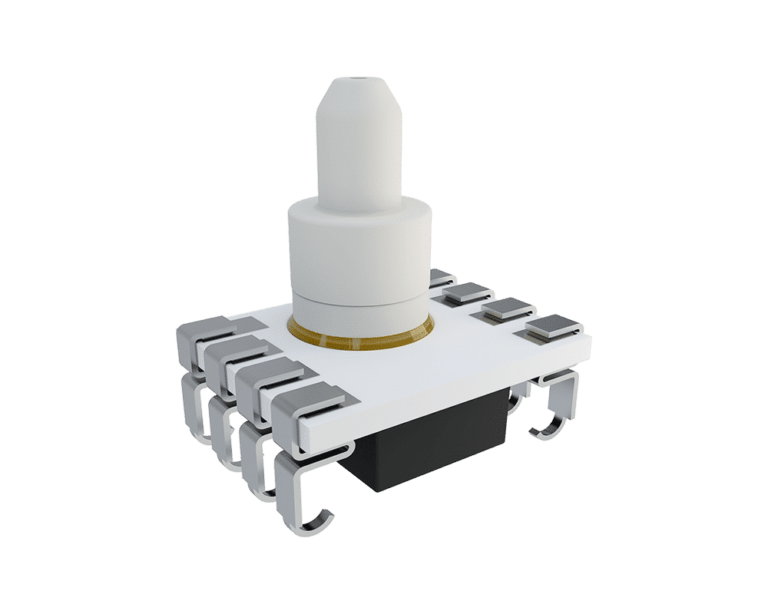

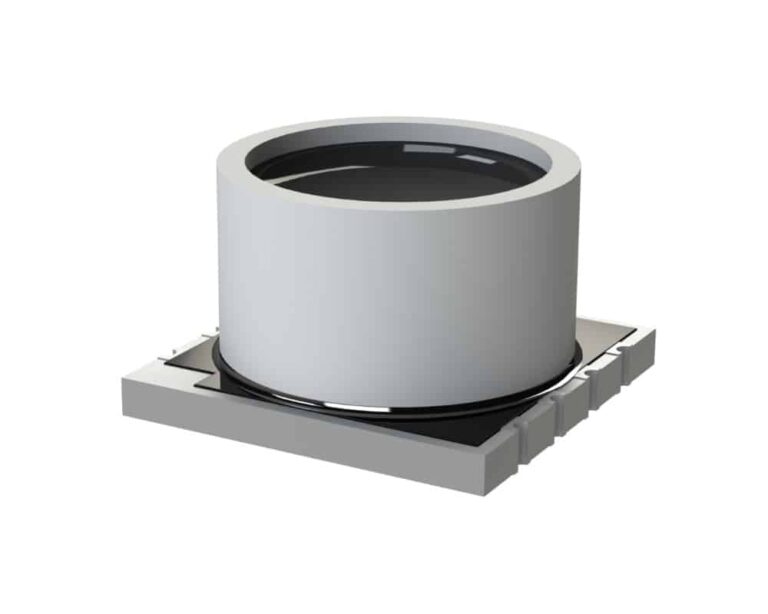

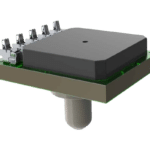

We also design and manufacture packaged pressure sensors for integration into the various applications of our customers. Some examples of our packaged sensors are the fully compensated TR Series, ideal for mass production in the automotive industry; the passively compensated BP Series, ideal for the room-temperature environment of medical devices; and the uncompensated RS Series, ideal for soldering and later calibrating on a control board.

In addition to our standard products designed for various applications, we also customize products to meet the specific needs of our customers (e.g., sensitivity, resistance, calibration). If the requirements are feasible and the NRE payment is sufficient, we will work closely with those customers who require a customized sensor.

Having a fab on site allows us to ensure high quality.* All of our products are RoHS and REACH compliant and AEC-Q100 compliant. But even if issues do arise, we are committed to quality and customer service. We will provide our customers with solutions. For our official website, please visit www.meritsensors.com