Application Note / Case Study

By: Omer Mirza, Joint Managing Director, Rhopoint Components

Introduction

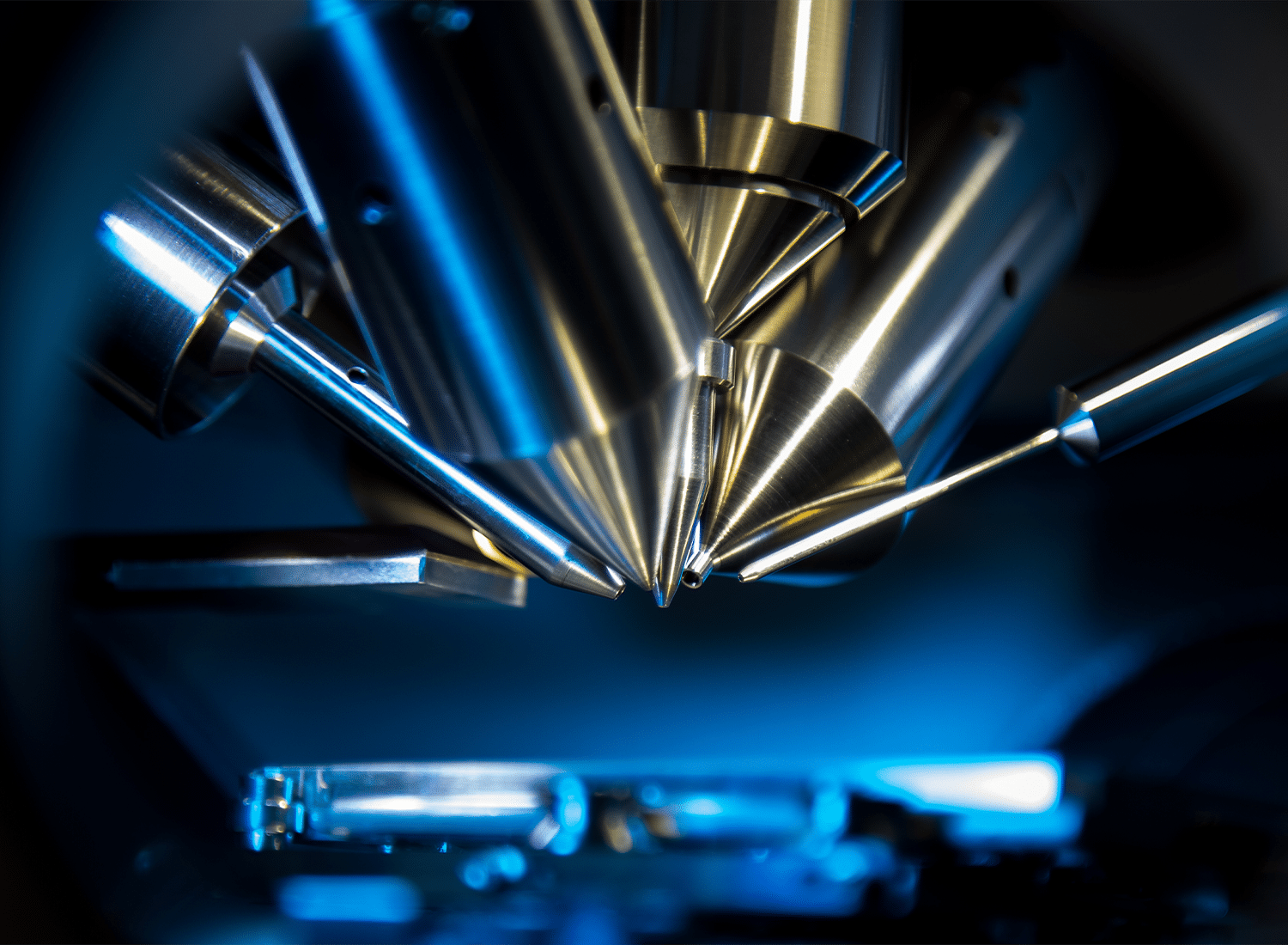

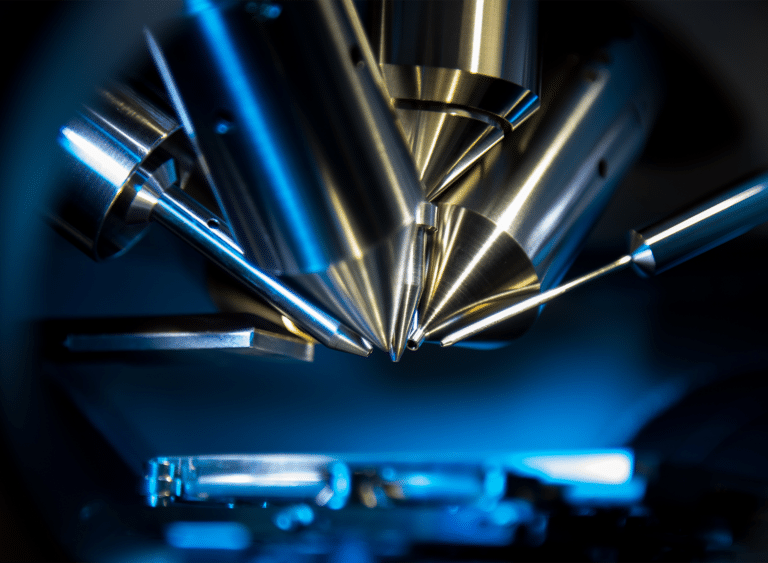

For more than two decades, Rhopoint Components has supported a leading manufacturer of high voltage power supplies in advancing high voltage design through precise component engineering and close technical collaboration. The customer’s products are at the core of demanding applications such as X-ray imaging, mass spectrometry and analytical instrumentation, areas where voltage accuracy, thermal stability and long-term consistency are essential to system safety and measurement integrity.

In these environments, success depends not only on high-quality components but also on the engineering partnerships that ensure each part performs optimally within the circuit. Rhopoint’s contribution has been to deliver that deeper integration between component performance and system-level precision.

Engineering Challenge: Precision at High Voltage

High voltage power supplies present a unique set of challenges. They must sustain output stability under load, preserve linearity across voltage ranges exceeding 1 kV, and remain highly predictable over extended lifetimes. Even a small deviation in resistance or capacitance can propagate into significant instability, affecting control loop behaviour or calibration accuracy.

The customer’s designs operate within tightly controlled feedback networks and voltage dividers where long-term consistency cannot be compromised. As these systems evolve to meet higher performance targets and stricter regulatory standards, Rhopoint has played a key role in helping identify, adapt, and validate precision component solutions to maintain reliability under increased electrical stress.

System-Level Benefits Through Collaboration

Rhopoint’s technical team works directly with the customer’s design engineers from early concept definition through qualification and ongoing supply support. This approach combines detailed electrical modelling, component testing, and continuous feedback to ensure each design stage aligns with the required precision and safety profile.

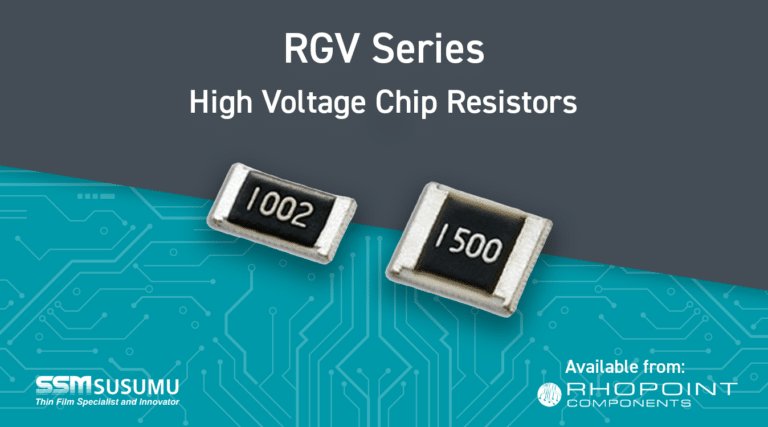

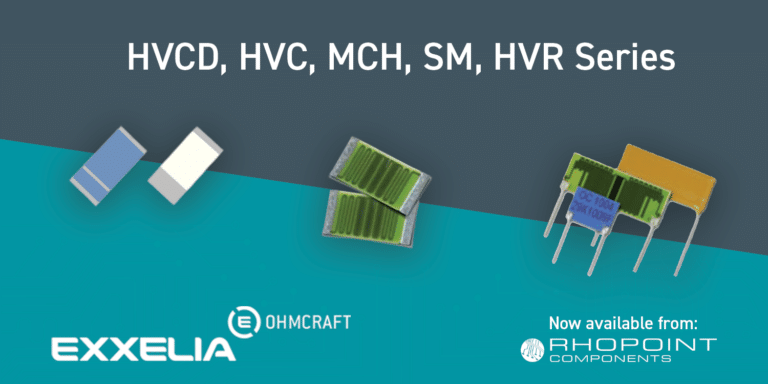

When the customer began updating their supply range to integrate higher efficiency and improved control accuracy, several critical components were approaching end-of-life. Rhopoint coordinated with manufacturing partners Caddock, Isabellenhuette, Exxelia Ohmcraft, SRT Resistor Technologies, Susumu, VPG Foil Resistors, ISOCOM and SRT Microceramique to pre-qualify suitable equivalents and validate them under representative test conditions. This prevented costly requalification delays and avoided the need for layout redesigns, enabling smooth production continuity.

Such collaboration has not only improved output stability and manufacturing efficiency but also strengthened long-term performance predictability across the customer’s full product range.

Precision as a Performance Enabler

The combined precision characteristics of the supplied component of low temperature coefficient, tight tolerance and stable dielectric properties are key enablers of consistent control under high voltage. In a voltage feedback network, for example, even minor drift in resistor values alters divider ratios, causing deviations in measured output. Components with temperature coefficients as low as a few parts per million per degree Celsius eliminate these errors, stabilising system calibration over extended operating cycles.

Similarly, in high-voltage filter networks, stable capacitor dielectrics minimise transient distortion during load changes, maintaining clean output waveforms and protecting downstream circuitry. These fine levels of electrical control translate directly into improved repeatability, lower noise, and extended service intervals in complex analytical and imaging equipment.

While these improvements occur at the component level, their real value emerges in system-level reliability and operational confidence.

Reliability, Longevity, and Application Integrity

In high voltage systems, reliability is synonymous with safety. Over two decades of deployment, our customer has reported zero failures in several long-term Rhopoint-supplied component lines, a record that underscores both component resilience and careful system integration.

The customer’s product platforms often remain in service for over ten years, sometimes across multiple generations of equipment. Maintaining component availability and stable performance through such extended life cycles requires not only durable materials but also foresight in obsolescence management. Rhopoint provides early visibility of supplier roadmap changes and arranges advanced qualification of successor parts, ensuring unbroken support throughout each platform’s lifetime.

This proactive continuity has allowed our customer to maintain consistent product performance even as the global component landscape evolves.

Design Philosophy: Proven Foundations for Innovation

The customer’s engineering philosophy values evolution rather than radical redesign. Each generation of power supplies builds upon a foundation of validated designs, refined to improve efficiency, control resolution, or safety compliance. Such gradual advancement depends on proven component stability and a trustworthy technical supply chain.

Rhopoint’s long-standing relationship with the design team provides deep historical insight into performance behaviour and field data. When new specifications exceed the limits of an existing component, Rhopoint facilitates the development of tailored or custom versions that preserve critical parameters such as resistance drift, voltage coefficient, and insulation reliability. This collaborative tuning ensures new designs maintain continuity with past performance benchmarks while enabling further innovation.

Guidance for New High Voltage Designers

For engineers entering high voltage development, system accuracy and reliability depend heavily on understanding factors that are often invisible in low voltage work. Rhopoint recommends considering the following during early design:

- Study voltage coefficient effects across the full operating range.

- Model physical layout to manage thermal gradients and electric field stress.

- Verify long-term insulation resistance and partial discharge characteristics.

- Incorporate screening processes for matching and drift control.

- Engage specialist suppliers who can support simulation, testing, and design reviews.

High voltage engineering requires predictive design and disciplined validation. Partnering with knowledgeable suppliers ensures performance reliability is established from the first prototype, not corrected after field feedback.

Looking Forward: The Next Phase of High Voltage Design

The next generation of high voltage systems will combine higher density, lower power loss and greater functional safety. Component-level innovations – improved thin-film stability, advanced encapsulants, and miniaturised divider architecture will allow compact, higher-resolution control modules while maintaining isolation and reliability.

Rhopoint continues to build upon two decades of experience supporting this customer and others across the sector. By integrating technical insight and extensive component knowledge, Rhopoint helps manufacturers achieve precise, reliable and safe high voltage systems that power the next decade of analytical and inspection technologies.