Please be advised that due to the ongoing supply issues with raw materials affecting the global electronics industry, as well as an increase in orders received by our manufacturing partners, a large number of products are facing increased lead times in recent months. For the latest lead time and stock availability, please contact one of our engineers who will be happy to discuss lead times further and the potential for alternative parts.

Oil & Gas

With extensive knowledge in the Oil & Gas market, we have successfully helped in projects with major blue-chip companies. From MWD, LWD and completion tools to artificial lift and chemical injection plus many more, we have the knowledge and products to help with whatever gets asked. Offering off-the-shelf products as well as offer many custom solutions to help you achieve your goals.

- Low profile, lightweight and precise pancake load cell

- Low off-axis sensitivity

- Barometric compensation

- Shock and vibration resistant

- Compact size with integral base with integral cable

- Life cycle of 10 million

- 5 point calibration record traceable to NIST (0, 50%, 100%, 50%, 0)

- Temperature effect on zero ±0.002% FSO/°F

- Temperature effect on span ±0.002% Reading/°F

- Zero balance ±1% FSO

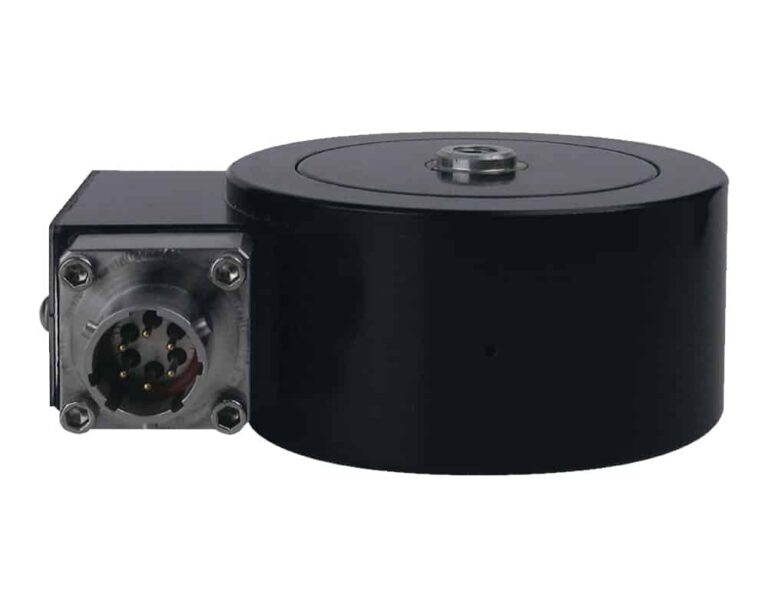

- Low profile, lightweight and precise pancake load cell

- Low off-axis sensitivity

- Barometric compensation

- Shock and vibration resistant

- Compact size with integral base and bolt-on flange electrical connector

- Life cycle of 10 million

- 5 point calibration record traceable to NIST (0, 50%, 100%, 50%, 0)

- Temperature effect on zero ±0.002% FSO/°F

- Temperature effect on span ±0.002% Reading/°F

- Zero balance ±1% FSO

- Shackle ready, rod end load cell

- In line tension

- Variety of thread combinations

- Shock and vibration resistant

- All welded stainless steel construction

- 5 point calibration record traceable to NIST (0, 50%, 100%, 50%, 0)

- Temperature effect on zero ±0.005% FSO/°F

- Temperature effect on span ±0.005% Reading/°F

- Zero balance ±1% FSO

- General purpose rod end compression and tension load cell

- High off-axis capability of up to 20% of full scale loads

- Variety of thread combinations available

- Shock and vibration resistant

- All welded stainless steel construction

- 5 point calibration record traceable to NIST (0, 50%, 100%, 50%, 0)

- Temperature effect on zero of ±0.005% FSO/°F

- Temperature effect on span ±0.005% Reading/°F

- Zero balance ±1% FSO

- Compact, high capacity rod end compression and tension load cell

- Environmentally sealed

- Low defection

- Shock and vibration resistant

- High strength tool steel

- 5 point calibration record traceable to NIST (0, 50%, 100%, 50%, 0)

- Temperature effect on zero ±0.005% FSO/°F

- Temperature effect on span ±0.005% Reading/°F

- Zero balance ±1% FSO

- General purpose subminiature compression load cell

- Small size

- Shock and vibration resistant

- All welded stainless steel

- 5 point calibration record traceable to NIST (0, 50%, 100%, 50%, 0)

- Temperature effect on zero ±0.01% FSO/°F

- Temperature effect on span ±0.01% Reading/°F

- Zero balance ±3% FSO

- General purpose subminiature tension or compression load cell

- Small size

- Shock and vibration resistant

- All welded stainless steel

- 5 point calibration record traceable to NIST (0, 50%, 100%, 50%, 0)

- Temperature effect on zero ±0.01% FSO/°F

- Temperature effect on span ±0.01% Reading/°F

- Zero balance ±3% FSO

- Surface-mount high temperature thin film chip resistor

- Temperature range of −55°C to +230°C

- Maximum voltage of 50V

- Thin film structure enabling low noise and anti-sulfur

- AEC-Q200 compliant

- Surface-mount high temperature thin film chip resistor

- Temperature range of −55°C to +230°C

- Maximum voltage of 100V

- Thin film structure enabling low noise and anti-sulfur

- AEC-Q200 compliant

- Surface-mount high temperature thin film chip resistor

- Temperature range of −55°C to +230°C

- Maximum voltage of 150V

- Thin film structure enabling low noise and anti-sulfur

- AEC-Q200 compliant