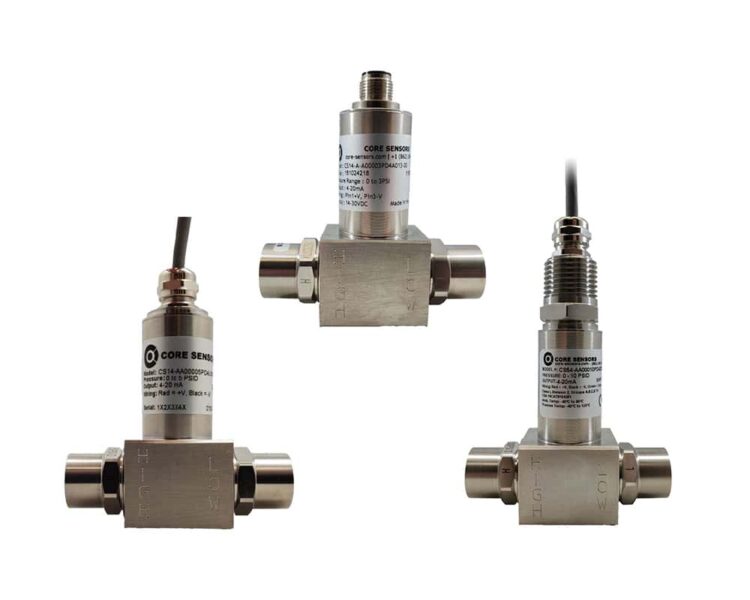

The CS84 intrinsically safe differential pressure transducer series from Core Sensors is a high-strength sensor designed for differential pressure measurements of liquids and gases in Class I, Division 1 intrinsically safe environments. The CS84 all welded stainless steel construction provides a minimum IP65 rating. Excellent stability is achieved with the 316L SS oil filled sensor element over a wide operating temperature range of -20 to +80°C (Electrical Connection “F”, DIN 43650-A) while offering corrosion resistance against various liquids and gases. Differential pressure ranges up to 50 PSI are available with 1/4″ MNPT or FNPT process connections. A wide range of configurable options make the CS84 a versatile pressure transducer that can be designed to operate in some of the harshest conditions.

The CS84 is the ideal solution for differential pressure measurement in hazardous applications such as filter condition monitoring, sealed tank level measurement, and flow measurement across an orifice.

The CS84 features a fully welded design without any internal O-rings or seals, allowing for wet/wet, wet/dry, or dry/dry applications. Differential pressures are available as low as 1 PSID up to 50 PSID in both uni-directional and bi-directional. Multiple electrical connections and outputs are available

- Intrinsically safe differential pressure transducer

- Differential pressure up to 50 PSI

- Maximum line pressure of 500 PSI **

- Bi-directional pressure ranges available

- Accuracy of ≤±0.25% BFSL (≤±0.5% BFSL 2 PSI & below) *

- Stability of ≤±0.25% of FS (1 year)

- Pressure cycles of 4 million

- Overpressure of 2X or 500 PSI (whichever is less, configured differential pressure) ***

- Burst pressure of 3x (configured differential pressure) ***

- Maximum differential pressure

- Temperature range −40°C to +80°C (−20°C to +80°C for Electrical Connection “F”, DIN 43650-A)

- Media temperature range −40°C to +125°C (−40°C to +105°C for Electrical Connection “F”, DIN 43650-A)

- Electrical output options of 4-20mA, 1-5V, 1-6V, 0.5-4.5V ratiometric or 0.5-2.5V non-ratiometric

- 316L SS diaphragm / oil filled sensor element

- All welded stainless steel construction for a minimum IP65 rating ****

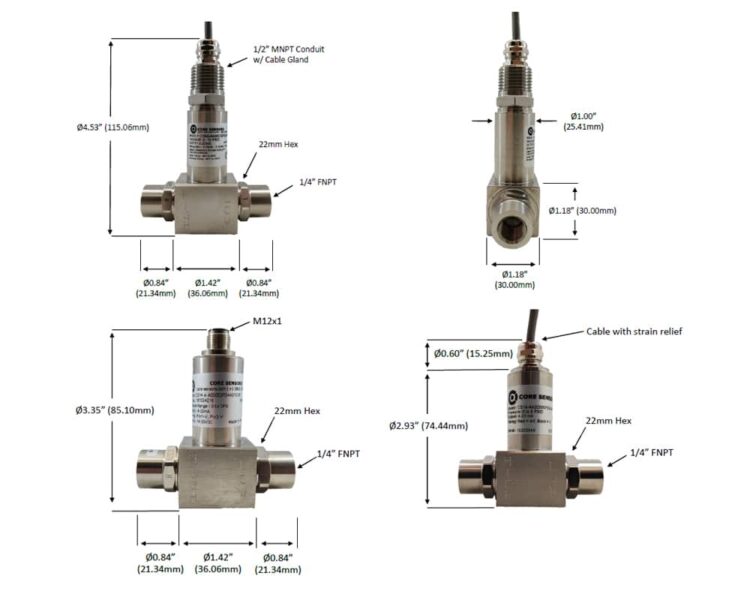

- 1/4” NPT or FNPT process connections

* Accuracy includes non-linearity, hysteresis and non-repeatability

** Max line pressure is the highest common mode pressure that can be applied to the sensor without damage

*** Overpressure and burst pressure are the maximum differential pressure that can be applied to the high or low side before damage to the sensor will occur

**** IP Rating applies when the electrical connector is attached with the appropriate ingress protection and is dependent on the electrical termination selected. Contact us for more information.

Approvals for the Core CS84 series include:

- CSA Class I, Division 1 Groups C,D T4

- Class I, Zone 0 AEx ia IIB T4 Ga (Ex ia IIB T4 Ga)

- ABS (American Bureau of Shipping)

- CE

Note: Must use an approved barrier to maintain listed certifications. See page 4 of the datasheet for entity parameters.

Typical applications for the CS84 intrinsically safe differential pressure transducer include:

- Filtration

- External fuel tank level measurement

- Compression systems

Core Sensors design and manufacture high-quality sensors for measuring pressure and temperature properties for industrial and hazardous applications worldwide. Core offers solutions for industrial, submersible, differential and hazardous applications in both standard and custom packaging. In-house design and manufacturing capabilities along with strategic manufacturing partners allow Core to create solutions to some of the most complex sensor requirements. Please visit https://core-sensors.com for more information.