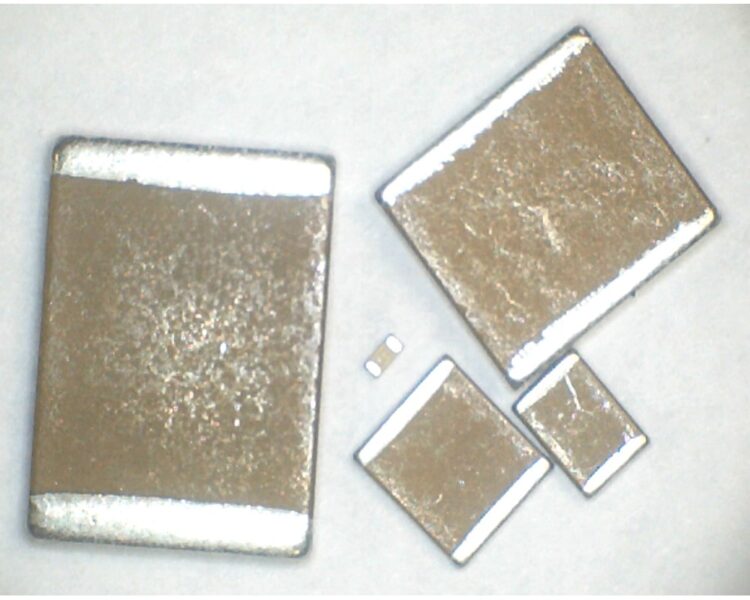

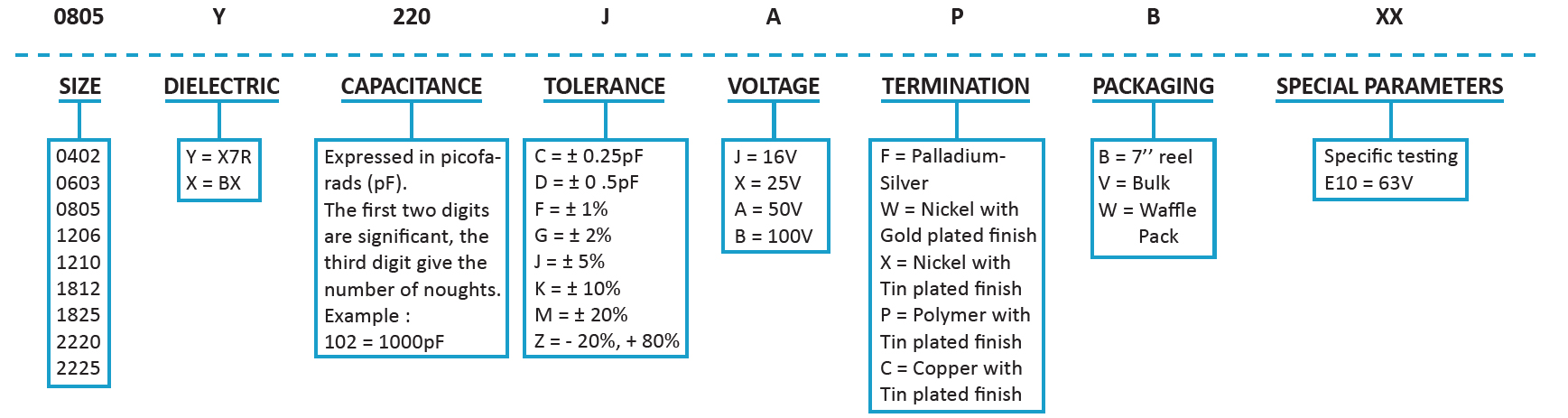

The X7R low voltage, stable ceramic chip MLCC capacitor series from SRT Microcéramique offers a wide range of options to suit any demand, including capacitance between 100pF to 8.2µF across a range of chip sizes from 0402 to 2225, a wide selection of tolerances (±0.25pF, ±0.5pF, ±1%, ±2%, ±5%, ±10%, ±20% and -20% to +80%), voltages (16V, 25V, 50V or 100V) and a range of terminations. As with all SRT-MC components, the X7R capacitors are popular in safety-critical industries thanks to their excellent quality and reliability. Their operating temperature is between -55°C and +125°C.

- Low voltage ceramic chip MLCC capacitor

- Available in capacitance ratings between 100pF and 8.2µF

- Available in standard chip sizes from 0402 to 2225

- Dissipation factor under 0.025 at 1kHz for C ≥ 1nF and under 0.025 at 1MHz for C ≤ 1nF

- Selection of Voltage ratings: 16V, 25V, 50V or 100V

- Selection of tolerances: ±0.25pF, ±0.5pF, ±1%, ±2%, ±5%, ±10%, ±20% and -20% to +80%

- Temperature range between -55°C and +125°C

Termination options available include:

- Palladium-Silver

- Gold-plated Silver

- Tin-plated Nickel

- Tin-plated Copper

- Flexible Tin-plated polymer (Microflex), improving the resistance to brittle fracture if the board is subject to flexion or vibration

While the X7R series offers a large number of options, customisation is possible on all SRT Microcéramique components – if none of the given options are suitable for your application, please contact us to discuss the custom solutions available.

The dielectric strength test for the low voltage X7R capacitors is performed per method 103 or EIA 198-2-E with 250% of the rated voltage applied.

Typical applications for the SRT-MC X7R series of low voltage ceramic capacitors include:

- Passing

- Coupling

- Filtering

- Blocking

The below table gives the specifications overview for each low voltage capacitor model available within the X7R series (16V-100V):