Please be advised that due to the ongoing supply issues with raw materials affecting the global electronics industry, as well as an increase in orders received by our manufacturing partners, a large number of products are facing increased lead times in recent months. For the latest lead time and stock availability, please contact one of our engineers who will be happy to discuss lead times further and the potential for alternative parts.

About SRT Microcéramique

SRT-Microcéramique is a French manufacturer of ceramic capacitors ( MLCC) present on the European market for more than 30 years.

In the permanent listening of our customers, our objective is to supply condensers in short times for any applications, including the most demanding.

Quality is our first objective. A process of qualification and follow-up of processes with clean means is in place.

We are particularly involved in the applications of severe environments that are the high temperature, the high voltage, the high frequencies. These components are used in domains demanding as medical, aeronautics, defense and oil.

Besides ceramic capacitors, we also supply electromagnetic filters.

We are strongly involved in a process of innovation in the domains of condensers and filters which allow her to answer customers’ specific demands.

For their official website, please visit srt-microceramique.com

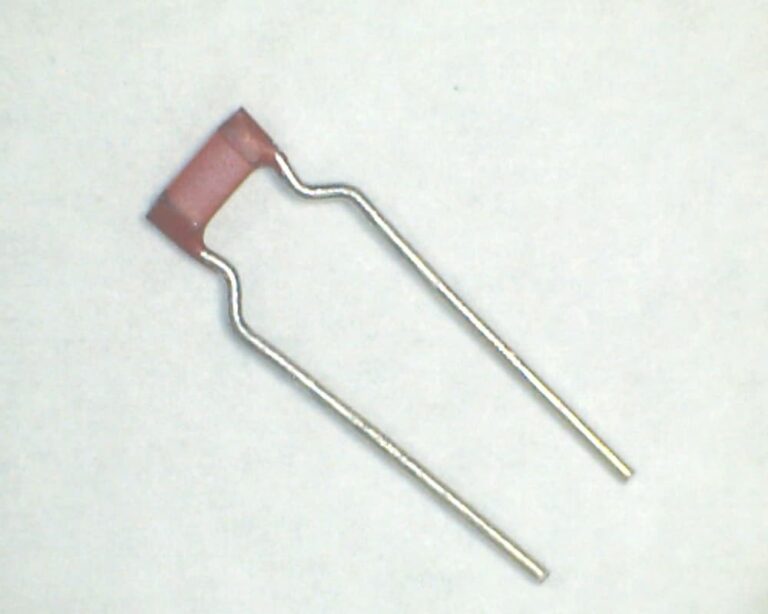

- Radial dipped NP0 capacitor series

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor up to 0.025

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Dielectric strength test performed per method 103 of EIA 198-2-E

- Radial dipped NP0 capacitor series

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor up to 0.025

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Dielectric strength test performed per method 103 of EIA 198-2-E

- Radial dipped X7R capacitor series

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor up to 0.025 at 1Vrms and 1kHz (or 1MHz)

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Dielectric strength test of 1.5Un + 100V for 5 seconds with 50mA maximum charging current

- Radial dipped X7R capacitor series

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor up to 0.025

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Dielectric strength test performed per method 103 of EIA 198-2-E

- Radial dipped X7R capacitor series

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor up to 0.025 at 1Vrms and 1kHz (or 1MHz)

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Dielectric strength test performed per method 103 of EIA 198-2-E

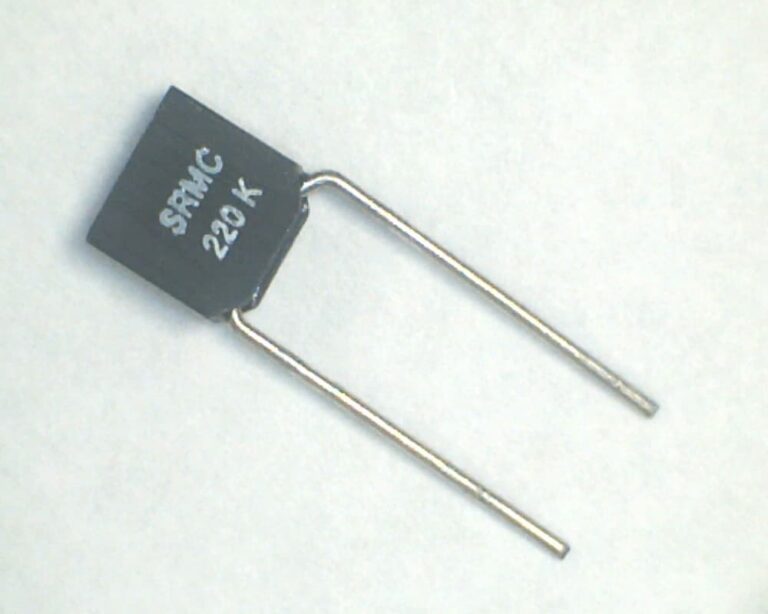

- Radial moulded capacitor series for military applications

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor up to 0.025 at 1Vrms and 1kHz

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Climatic Category 55/125/56

- Radial moulded capacitor series for military applications

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor up to 0.025 at 1Vrms and 1kHz

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Climatic category: 55/125/56

- MLCC RF power, high frequency capacitors for RF instruments, lasers and similar applications

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor under 5.10-4 at 1Vrms and 1MHz for values ≤ 1000pF and under 5.10-4 at 1Vrms and 1KHz for values > 1000pF

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Dielectric strength test performed per method 103 of EIA 198-2-E

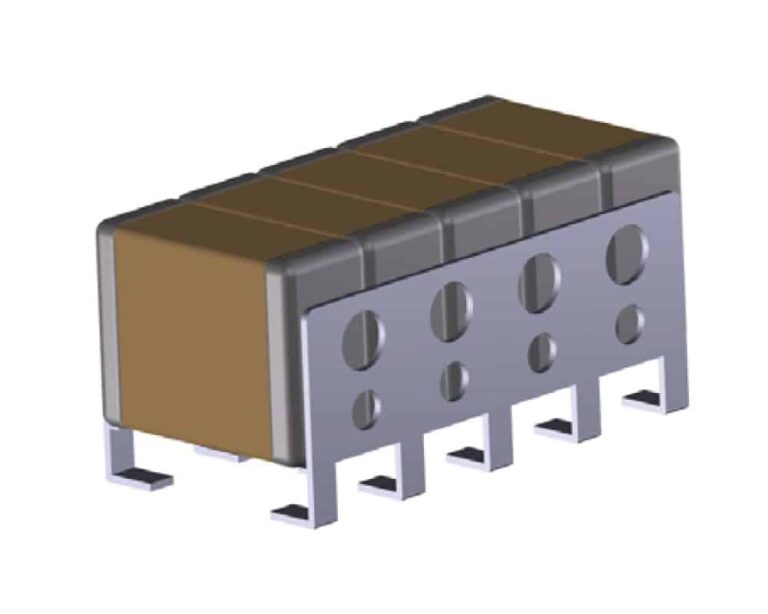

- NP0 high capacitance value capacitor stacks, ideal for SMPS applications

- Highest quality and reliability, suitable for safety-critical industries

- Dissipation factor 10.10-4 maximum

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less

- Dielectric withstanding voltage of 2.5Un for 5s with 50mA maximum charging current

- X7R high capacitance value capacitor stacks, ideal for SMPS applications

- Highest quality and reliability, suitable for safety-critical industries

- Maximum dissipation factor of 2.5% at 1Vrms, 1kHz, 25°C

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less

- Dielectric withstanding voltage of 2.5Un for 5s with 50mA maximum charging current

- Ceramic chip ceramic capacitor

- Highest quality and reliability, suitable for safety-critical medical applications

- Dissipation factor maximum of 2.5% (except for 25V models with 3.5% maximum)

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less and 125°C/Un 104 MΩ or 100 Ohm-Farad whichever is less

- Dielectric withstanding voltage of 250% of rated voltage for 5s + 1s, 50mA maximum

- X7R capacitor stacks, ideal for input/output filtering in SMPS applications

- Highest quality and reliability, suitable for safety-critical industries

- Maximum dissipation factor of 2.5% at 1Vrms, 1kHz, 25°C

- Insulation resistance of 25°C/Un 105 MΩ or 1000 Ohm-Farad whichever is less

- Dielectric withstanding voltage of 2.5Un for 5s with 50mA maximum charging current

Calculators and Converters

Work out what you need for your project. Go to calculators and convertors