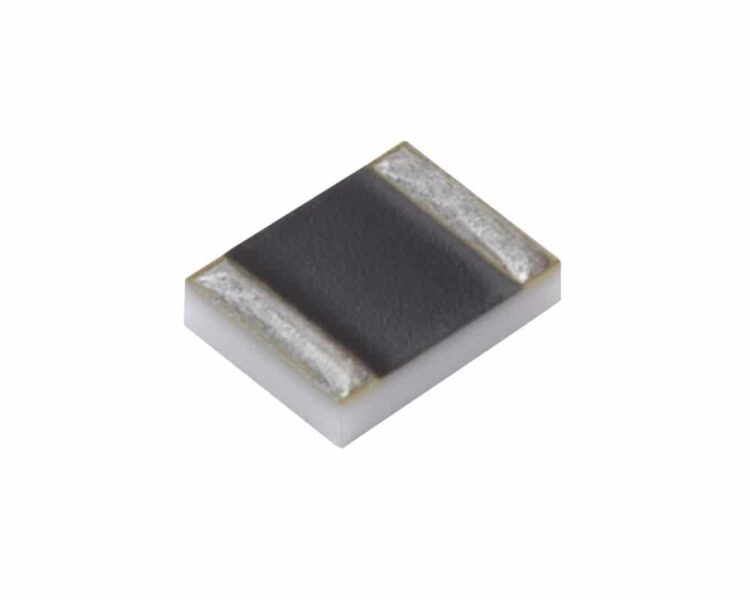

The RBD ultra-precision current sense resistor series from Alpha Electronics offers low resistances of between 0.01Ω and 1Ω all in a small 2-terminal flip-chip package. By utilising Alpha’s Bulk Metal® foil resistor technology, they are able to offer low tolerances down to ±0.5% as well as a low TCR of ±10 ppm/°C (between -25°C and +125°C) both within the resistance range of 0.1Ω to 1Ω.

- Ultra-precision current sense flip-chip resistor

- Available in any resistance between 0.01Ω and 1Ω

- 2-terminal current sense resistor in a flip-chip surface-mount package

- Power rating of 0.5W at +70°C

- Tolerances as low as ±0.5% over the resistance range of 0.1Ω to 1Ω

- Tight TCR available of ±10 ppm/°C over the resistance range of 0.1Ω to 1Ω

- Maximum rated operating temperature +70°C

- Temperature range from -65°C up to +155°C

The RBD ultra-precision current sense resistor series offer ultra-precision thanks to Alpha’s Bulk Metal® foil resistor technology, making them suitable for the most demanding precision applications.

Temperature rise of resistor surface can be optimised by using a board made of metal. This keeps the temperature rise very low allowing increased power rating of the parts i.e. 2W at +70°C. Please keep the temperature of board less than +90°C when using glazed epoxy board.

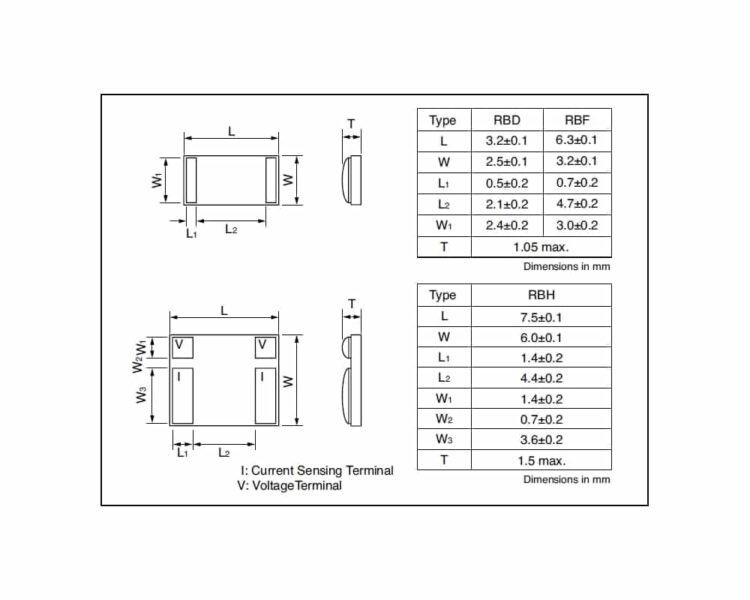

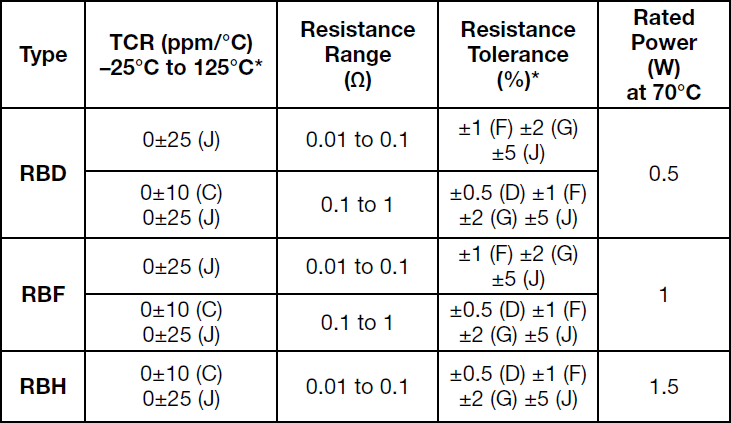

The below table gives the full specifications for each resistor model available including the Alpha RBD series:

* Symbols parenthesized are for part number composition