Please be advised that due to the ongoing supply issues with raw materials affecting the global electronics industry, as well as an increase in orders received by our manufacturing partners, a large number of products are facing increased lead times in recent months. For the latest lead time and stock availability, please contact one of our engineers who will be happy to discuss lead times further and the potential for alternative parts.

UL

Underwriters Laboratories® Inc. (UL) is an independent product safety certification organization Based in Northbrook, Illinois.

UL develops standards and test procedures for products, materials, components, assemblies, tools and equipment, chiefly dealing with product safety.

UL does not “approve” products. Rather it evaluates products, components, materials and systems for compliance to specific requirements, and permits acceptable products to carry a UL certification mark, as long as they remain compliant with the standards.

- Metal clad wire wound resistor

- Resistance options from 0.6Ω up to 144Ω

- Power rating of up to 720W (on heatsink)

- Tolerance options between ±1% and ±10.0%

- TCR of +260 ppm/°C maximum

- For Non UL Approval see the IRM

- Metal clad wire wound resistor

- Resistance options from 0.7Ω up to 135Ω

- Power rating of up to 750W (on heatsink)

- Tolerance options between ±1% and ±10.0%

- TCR of +260 ppm/°C maximum

- For Non UL Approval see the IRM

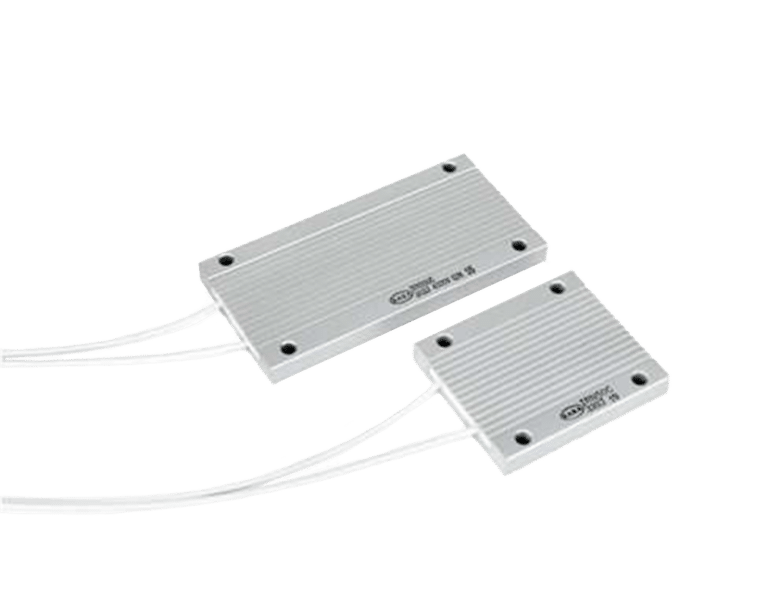

- Narrow and Flat type metal clad wire wound resistor

- Resistance options from 1Ω up to 420Ω

- Power rating of 50W (on a heat sink)

- Tolerance options between ±0.5% and ±10.0%

- TCR of +260 ppm/°C maximum

- For Non UL Approval see the IRN Series

- Narrow and Flat type metal clad wire wound resistor

- Resistance options from 1Ω up to 1.1kΩ

- Power rating of 100W (on a heat sink)

- Tolerance options between ±0.5% and ±10.0%

- TCR of +260 ppm/°C maximum

- For Non UL Approval see the IRN Series

- Narrow and Flat type metal clad wire wound resistor

- Resistance options from 1Ω up to 1.75kΩ

- Power rating of 150W (on a heat sink)

- Tolerance options between ±0.5% and ±10.0%

- TCR of +260 ppm/°C maximum

- For Non UL Approval see the IRN Series

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 5 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium vertical housing

- UL approved

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Rated power 600W(Heatsink) / 330W (In air)

- UL approved

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Option of flying leads, parallel or series connections

- Metal clad wire wound resistor

- Option of flying leads, parallel or series connections

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- UL approved

- Cement moulding with an extruded aluminium housing

- Short time overload of 10 x power rating is 5 seconds