Please be advised that due to the ongoing supply issues with raw materials affecting the global electronics industry, as well as an increase in orders received by our manufacturing partners, a large number of products are facing increased lead times in recent months. For the latest lead time and stock availability, please contact one of our engineers who will be happy to discuss lead times further and the potential for alternative parts.

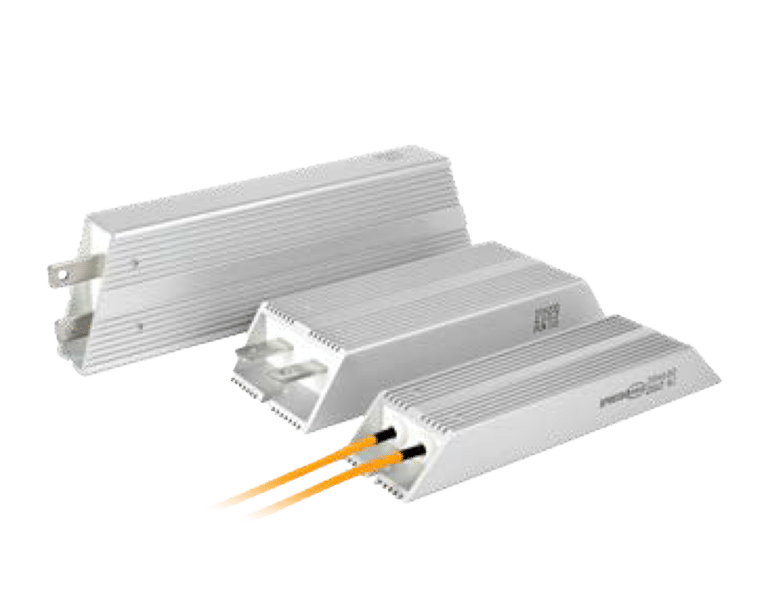

IRH series

Experience engineering precision with the IRH (Horizontal) Series, delivering high-performance metal-clad wire-wound resistors for diverse applications, from motor drives to electric vehicle charging. Ranging from 60W to 500W, these resistors offer versatile options with an inductive resistance span of 0.1Ω to 6.8kΩ and non-inductive range of 0.1Ω to 3kΩ. These resistors boast an exceptional Tolerances of ±0.5%, ±1%, ±2%, ±5%, and ±10% and a Temperature Coefficient of Resistance (TCR) of ±260ppm/℃ max. The aluminum housing ensures rugged protection, suitable for demanding environments making it suitable for applications such as motor drives, braking and snubber, EV charging and power sources for industrial equipment. The IRH Series, also available as a vertical model (IRV), provides flexibility with options like flying leads or tab terminals. For UL/CE approval, explore the ULH/ULV Series. Elevate your engineering projects with the precision of the IRH Series from www.raraohm.com.

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 5 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 10 x power rating is 5 seconds

- Metal clad wire wound resistor

- Option of flying leads (tab terminals are standard)

- Inductive or non-inductive design

- Insulation resistance of 20MΩ minimum

- Temperature range of -55°C up to +200°C

- Extruded aluminium horizontal housing

- Short time overload of 10 x power rating is 5 seconds