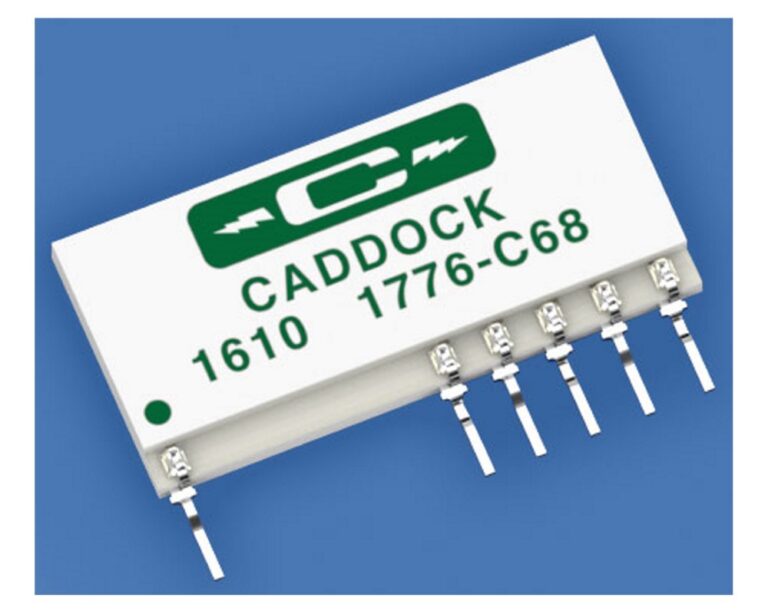

-40 to +85°C series

- Precision voltage dividers

- Resistance ranges from 900Ω to 10MΩ

- Absolute Tolerance of +0 -0.5%, ±0.1% or ±0.25%

- VCR from ±0.02 ppm/V to ±0.5 ppm/V

- Voltage rating of 750V up to 1.2kV

- Temperature range 1 from -40°C to +85°C Temperature range 2 from 0°C to +70°C

- Steel mill pressure transducer

- Pressures up to 350 Bar

- Accuracy down to ≤±0.25% BFSL

- Pressure cycles of >100 million

- Burst pressure of 10X or 20,000 PSI (whichever is less)

- IP69 protection against high pressure washdown

- Integral snubber protects against pressure transients

- Industrial pressure transducer

- Pressure ranges from vacuum up to 45,000 PSI

- Accuracy down to ≤ ±0.25% BFSL

- Stability (1 year) of ≤ ±0.25% of FS

- Overpressure of 2x minimum

- Temperature range from -40°C to +85°C

- Media Temperature from -40°C to +120°C

- Submersible pressure transducer

- Pressure ranges from 1 to 100 PSI

- Accuracy down to ≤±0.25% BFSL

- Stability (1 year) of ≤±0.25% of FS

- Pressure cycles of 50 million

- Overpressure of 2x minimum

- Burst pressure of 5x or 500 PSI

- Non-Clogging submersible pressure transducer

- Pressure ranges from 2 PSI to 50 PSI

- Flush diaphragm prevents clogging

- Hastelloy C276 diaphragm material

- IP68 rated

- Operating temperature of -40 to +85°C

- Compensated temperatures from 0 to +55°C

- Industrial temperature transmitter

- RTD sensor type, PT100, Class B

- Media temperature range of -40°C up to +200°C *

- Operating temperature range of -40°C up to +85°C

- Total error at RT & FS of ≤±1%

- Maximum pressure of 5,000 PSI

- Amplified 4-20mA or 1-5V output signal

- Explosion-Proof Pressure Transducer

- Pressure ranges from 50 PSI to 30,000 PSI

- One piece diaphragm design – No internal O-rings or welds

- Factory sealed stainless steel case – Withstands harsh environments

- Accuracy of ≤±0.25% BFSL at 25°C (<10,000 PSI)

- Pressure cycles of 100 million

- Overpressure of 2x minimum

- Intrinsically safe pressure transducer

- Pressure ranges available from 50 PSI up to 30,000 PSI

- Temperature range −40°C to +85°C

- Accuracy of ≤ ±0.25% BFSL

- Burst pressure of 5x or 60,000 PSI whichever is less

- Stability (1 year) of ≤ ±0.25% of FS

- Pressure cycles of 100 million

- Intrinsically safe submersible pressure transducer

- Pressure ranges from 1 PSI up to 50 PSI

- Accuracy of ≤±0.25% BFSL

- Stability of ≤±0.25% of FS (1 year)

- Pressure cycles of 50 million

- Overpressure of 2x minimum

- Burst pressure of 5x or 250 PSI

- TMR analog magnetic sensor

- Operate sensitivity from -80 G to +80 G (typical)

- Average supply current of 1.5μA at 3V (typical)

- Supply voltage range of 1.7V to 5.5V

- Linear Analog Voltage Response

- Operating frequency of 100Hz

- SOT-23-3 (531) or LGA4 (532) package

- TMR digital push-pull magnetic sensor

- Operate sensitivity of 9 G (typical)

- Average supply current of 135nA at 3V (typical)

- Supply voltage range of 1.7V to 5.5V

- Omnipolar push-pull response

- Operating frequency of 10 Hz

- SOT-23-3 (511) or LGA-4 (512) package

- TMR digital push-pull magnetic sensor

- Operate sensitivity of 9 G (typical)

- Average supply current of 1.3μA at 3V (typical)

- Supply voltage range of 1.7V to 5.5V

- Omnipolar push-pull response

- Operating frequency of 250Hz

- SOT-23-3 (511) package

- TMR digital push-pull magnetic sensor

- Operate sensitivity of 30 G (typical)

- Average supply current of 70nA at 3V (typical)

- Supply voltage range of 1.7V to 5.5V

- Omnipolar push-pull response

- Operating frequency of 2Hz

- SOT-23-3 (511) or LGA-4 (512) package

- TMR digital push-pull magnetic sensor

- Operate sensitivity of 30 G (typical)

- Average supply current of 1.3μA at 3V (typical)

- Supply voltage range of 1.7V to 5.5V

- Omnipolar push-pull response

- Operating frequency of 250Hz

- SOT-23-3 (511) package

- TMR digital push-pull magnetic sensor

- Operate sensitivity of 30 G (typical)

- Average supply current of 36μA at 3V (typical)

- Supply voltage range of 1.7V to 5.5V

- Omnipolar push-pull response

- Operating frequency of 10Hz

- SOT-23-3 (511) or LGA-4 (512) package

- TMR digital push-pull magnetic sensor

- Operate sensitivity of 15 G (typical)

- Average supply current of 12μA at 3V (typical)

- Supply voltage range of 1.7V to 5.5V

- Omnipolar push-pull response

- Operating frequency of 2500Hz

- SOT-23-3 (511) package